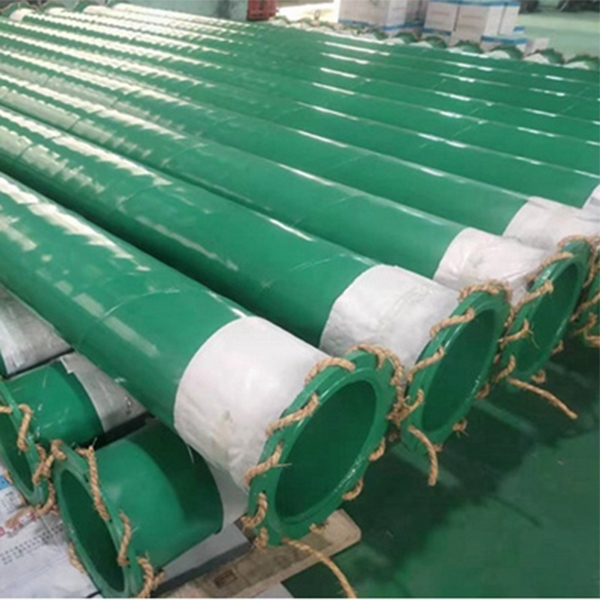

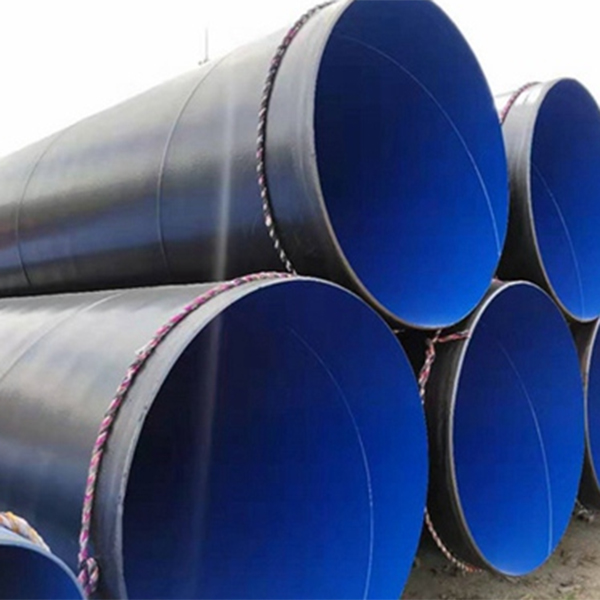

Pipa baja komposit galvanis kanggo pasokan banyu lan pemadam kebakaran nganggo plastik

Pipa banyu ditutupi plastik, Kanggo resin epoksi sing diowahi utawa bubuk poliethelin ing njero lan njaba pipa plastik sing dilapisi.

Pipa banyu sing dilapisi plastik, nduweni kinerja lengkap banget lan tahan karat sing kuat, panggunaan suhu njaba -40 ℃ - 90 ℃.Suhu pangiriman banyu sing ditrapake yaiku -30 ℃ - 80 ℃.Pipa baja plastik sing dilapisi kanggo pasokan banyu luwih unggul ing stabilitas kimia lan kinerja sanitasi, lan tundhuk karo standar evaluasi safety kanggo peralatan transmisi lan distribusi banyu lan bahan protèktif.

Pipa Banyu Dilapisi Plastik, Fitur Produk

Penyetor banyu dilapisi plastik tabung baja lumahing lapisan Gamelan, ayu, werna cahya external bisa dadi pilihan.Amarga tembok njero Gamelan, bisa nyegah breeding saka microorganisms, resistance cilik transmisi adi, bisa nambah aliran, nyimpen energi, digunakake kanggo kabeh jinis sumber banyu lan engineering got.

Pipa Banyu Dilapisi Plastik, Lingkup Aplikasi

Utamane digunakake kanggo ngombé pipa sumber banyu, lan banyu segara, banyu direklamasi, kimia lan petroleum, lan paling asam, alkali, uyah, utamané cocok kanggo pipa disarèkaké, urip layanan saka 50 taun.

Pipa Banyu Dilapisi Plastik, Indeks Kinerja

1, kekuatan lengkap ora kurang saka 1.6mpa;

2, ing test mlengkung antarane nutupi ora tiba mati, kedadean fraktur;

3, ing test flattening antarane nutupi ora tiba mati, kedadean fraktur;

4, ing tes kinerja kesehatan, selaras karo standar inspeksi GB / T219-1998;

5, lapisan njaba cocog karo standar inspeksi CJ / T120-2008;

6, kekuatan impact saka KG / cm> = 50, standar pengawasan selaras karo GB / T1732-1993.

Pipa Banyu Dilapisi Plastik, Standar Produk

CJ/T120-2008 "Pipa Baja Komposit Dilapisi Plastik kanggo Pasokan Banyu"

GB/T17219-1998 Kesehatan kinerja Indikator standar implementasine

Spesifikasi

| Item | Pipa banyu sing dilapisi plastik |

| Bahan | SPHC, Q195, Q215, Q235, Q345, SAE1010, SAE1020, Bahan Standar API, ASTM A53 A, B |

| OD | 10-1219(1/8''-48'') |

| WT | 0.7-13 |

| dawa | 2m-12m utawa minangka saben requirement pelanggan |

| Toleransi Kekandelan | + 5%- |

| lumahing | lenga / dicet |

| Ujung pipa | Ujung polos / Ujung Beveled / Utas kanthi kopling lan tutup |

| menehi tandha | Minangka saben requirement customer kang |

| Sdandard | ASTM/BS EN/DIN/GB |

| Sertifikat | ISO, BV, API |

| ODM / OEM | kasedhiya |

| Standar | ASTM A53,BS1387-1985,GB/T3091-2001,GB/T13793-92, GB/T6728-2002 |

| Bahan | Q195, Q215, Q235, Q345 |

| Teknik | Dilas |

| Panganggone | Mekanik & Pabrikasi, Struktur Baja, Gawe kapal, Bridging, Sasis mobil |

Komposisi kimia

| sasmita | C | Mn | Si | S | P | UTS (MPa) | YS (MPa) | EI(%) |

| Q235B | 0.12-0.20 | 0.30-0.70 | 0.30 | 0.045 | 0.045 | 375-500 | 235 | 26 |

| Q345B | 0.12-0.20 | 1.20-1.60 | 0.20-0.55 | ≤0,045 | ≤0,045 | 510-600 | 345 | 22 |

| 20# (GB) | 0.17-0.23 | 0.38-0.65 | 0.17-0.37 | ≤0,030 | ≤0,030 | 410-550 | ≥245 | ≥20 |

| GAMBAR UKURAN PIPA HDPE | |||||||||

| Dia | Penyimpangan | 0,4 Mpa | 0,5 Mpa | 0,6 Mpa | 0,8 Mpa | 1.0Mpa | 1.25Mpa | 1.6MPa | 2.0Mpa |

| kekandelan | kekandelan | kekandelan | kekandelan | kekandelan | kekandelan | kekandelan | kekandelan | ||

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm |

| 16 | 0.3 | 2.3 | |||||||

| 20 | 0.3 | 2.3 | 2.3 | ||||||

| 25 | 0.3 | 2.3 | 2.3 | 3 | |||||

| 32 | 0.3 | 2.3 | 2.4 | 3 | 3.6 | ||||

| 40 | 0.4 | 2.3 | 2.4 | 3 | 3.7 | 4.5 | |||

| 50 | 0.4 | 2.3 | 2.4 | 3 | 3.7 | 4.6 | 5.6 | ||

| 63 | 0.4 | 2.5 | 3 | 3.8 | 4.7 | 5.8 | 7.1 | ||

| 75 | 0.5 | 2.9 | 3.6 | 4.5 | 5.6 | 6.8 | 8.4 | ||

| 90 | 0.6 | 3.5 | 4.3 | 5.4 | 6.7 | 8.2 | 10.1 | ||

| 110 | 0.7 | 4.2 | 5.3 | 6.6 | 8.1 | 10 | 12.3 | ||

| 125 | 0.8 | 4.8 | 6 | 7.4 | 9.2 | 11.4 | 14 | ||

| 140 | 0.9 | 5.4 | 6.7 | 8.3 | 10.3 | 12.7 | 15.7 | ||

| 160 | 1 | 6.2 | 7.7 | 9.5 | 11.8 | 14.6 | 17.9 | ||

| 180 | 1.1 | 6.9 | 8.6 | 10.7 | 13.3 | 16.4 | 20.1 | ||

| 200 | 1.2 | 7.7 | 9.6 | 11.9 | 14.7 | 18.2 | 22.4 | ||

| 225 | 1.4 | 8.6 | 10.8 | 13.4 | 16.6 | 16.6 | 25.2 | ||

| 250 | 1.5 | 9.6 | 11.9 | 14.8 | 18.4 | 22.7 | 27.9 | ||

| 280 | 1.7 | 10.7 | 13.4 | 16.6 | 20.6 | 25.4 | 31.3 | ||

| 315 | 1.9 | 7.7 | 9.7 | 12.1 | 15 | 18.7 | 23.2 | 28.6 | 35.2 |

| 355 | 2.2 | 8.7 | 10.9 | 13.6 | 16.9 | 21.1 | 26.1 | 32.2 | 39.7 |

| 400 | 2.4 | 9.8 | 12.3 | 15.3 | 19.1 | 23.7 | 29.4 | 36.3 | 44.7 |

| 450 | 2.7 | 11 | 13.8 | 17.2 | 21.5 | 26.7 | 33.1 | 40.9 | 50.3 |

| 500 | 3 | 12.3 | 15.3 | 19.1 | 23.9 | 29.7 | 36.8 | 45.4 | 55.8 |

| 560 | 3.4 | 13.7 | 17.2 | 21.4 | 26.7 | 33.2 | 41.2 | 50.8 | 62.5 |

| 630 | 3.8 | 15.4 | 19.3 | 24.1 | 30 | 37.4 | 46.3 | 57.2 | 70.3 |

| 710 | 6.4 | 17.4 | 21.8 | 27.2 | 33.9 | 42.1 | 52.2 | 64.5 | 79.3 |

| 800 | 7.2 | 19.6 | 24.5 | 30.6 | 38.1 | 47.4 | 58.8 | 72.6 | 89.3 |

| 900 | 8.1 | 22 | 27.6 | 34.4 | 42.9 | 53.3 | 66.2 | 81.7 | |

| 1000 | 9 | 24.5 | 30.6 | 38.2 | 47.7 | 59.3 | 72.5 | 90.2 | |

Tampilan produk