A513 tabung baja kothak kanggo transportasi adi

A513 Steel Square Tubing, pipa baja persegi tembok tebal, pipa baja persegi diameter gedhe, pipa baja persegi mulus, pipa baja persegi paduan rendah, pipa baja persegi 135 * 135 * 10, pipa baja persegi menara crane, Q345B pipa baja persegi alloy rendah, 20 # pipa baja kothak mulus

A513 Steel Square Tubing, Minangka jeneng gawe katut, iku wangun kothak saka tabung, akeh jinis materi bisa mbentuk awak tabung kothak, medium ing, apa nggunakake, ngendi kanggo nggunakake, paling saka tabung kothak kanggo pipe baja kanggo mayoritas, biasane kanggo tabung kothak struktural, tabung kothak hiasan, tabung kothak bangunan lan ing.

A513 Steel Square Tubing, Iku jeneng kanggo tabung kothak, kang tabung padha dawa.Iki digawe saka baja Strip sawise Processing lan Rolling.Umume, jalur kasebut dibongkar, diratakake, dikerik lan dilas dadi tabung bunder, sing digulung dadi tabung persegi lan banjur dipotong dadi dawa sing dibutuhake.Biasane 50 batang saben bungkus.

A513 Steel Square Tubing, Ana TCTerms rapi lan las, tabung kothak rapi punika tabung extrusion ngecor rapi.Pipa baja persegi, pipa baja persegi tembok tebal, pipa baja persegi diameter besar, pipa baja persegi mulus, pipa baja persegi paduan rendah, pipa baja persegi 135*135*10, pipa baja persegi tower crane, Q345B pipa baja persegi paduan rendah, 20 # pipa baja persegi mulus

1. Analisis kinerja eksponensial saka tabung persegi - plastisitas

Plastisitas nuduhake kemampuan materi logam kanggo ngasilake deformasi plastik (deformasi permanen) tanpa karusakan ing beban.

2. Analisis indeks kinerja tabung kothak - atose

Kekerasan minangka ukuran ukuran hard utawa alus bahan logam.Saiki, cara sing paling umum digunakake kanggo nemtokake kekerasan ing produksi yaiku metode kekerasan indenter, yaiku nggunakake wangun geometris tartamtu saka sirah indenter ing beban tartamtu menyang permukaan bahan logam sing diuji, miturut derajat indentor kanggo nemtokake nilai atose sawijining.

Cara sing umum digunakake yaiku kekerasan Brinell (HB), kekerasan Rockwell (HRA, HRB, HRC) lan kekerasan Vickers (HV) lan metode liyane.

3. Analisis indeks kinerja tabung persegi - lemes

Kekuwatan, plastisitas, lan kekerasan sing dibahas ing ndhuwur minangka indikator sifat mekanik logam ing beban statis.Nyatane, akeh bagean mesin sing dioperasikake kanthi beban siklik, lan kesel bisa kedadeyan ing kahanan kasebut.

4. Analisis indeks kinerja pipa persegi - ketangguhan impact

Beban sing tumindak ing bagean kanthi kacepetan dhuwur diarani beban impact, lan kemampuan logam kanggo nolak karusakan ing beban impact diarani ketangguhan impact.

5. Analisis indeks kinerja pipa persegi - pipa baja persegi kekuatan, pipa baja persegi tembok tebal, pipa baja persegi diameter gedhe, pipa baja persegi mulus, pipa baja persegi paduan rendah, pipa baja persegi 135 * 135 * 10, pipa baja persegi menara crane , Q345B paduan rendah pipa baja persegi, 20 # pipa baja persegi mulus

Kekuwatan yaiku kemampuan materi logam kanggo nolak kegagalan (deformasi plastik utawa fraktur sing gedhe banget) ing beban statis.Amarga mode loading ing wangun mulet, komprèsi, mlengkung, shearing, supaya kekuatan uga dipérang dadi kekuatan tensile, kekuatan compressive, kekuatan mlengkung, kekuatan geser lan ing.Asring ana sambungan tartamtu ing antarane macem-macem kekuwatan, lan kekuatan tarik umume digunakake minangka penunjuk kekuatan paling dhasar.

Ukuran

| Ukuran by Inch (diameter) | kekandelan | Ukuran by MM (diameter) | kekandelan |

| inch | inch | mm | mm |

| 1/2" x 1/2" | 0,065" | 16mm × 16mm | 0.4mm ~ 1.5mm |

| Ukuran 3/4" x 3/4" | 0,049" | 18mm × 18mm | 0.4mm ~ 1.5mm |

| 0,065" | 20mm × 20mm | 0.4mm ~ 3mm | |

| 0,083" | 22mm × 22mm | 0.4mm ~ 3mm | |

| 0,120" | 25mm × 25mm | 0.6mm ~ 3mm | |

| 1" x 1" | 0,049" | 30mm × 30mm | 0.6mm ~ 4mm |

| 0,058" | 32mm × 32mm | 0.6mm ~ 4mm | |

| 0,065" | 34mm × 34mm | 1 mm ~ 2 mm | |

| 0,072" | 35mm × 35mm | 1 mm ~ 4 mm | |

| 0,083" | 38mm × 38mm | 1 mm ~ 4 mm | |

| 0,095" | 40mm × 40mm | 1 mm ~ 4,5 mm | |

| 0.109" | 44mm × 44mm | 1 mm ~ 4,5 mm | |

| 0,120" | 45mm × 45mm | 1 mm ~ 5 mm | |

| 1 1/8" x 1 1/8" | 0,035" | 50mm × 50mm | 1 mm ~ 5 mm |

| 0,049" | 52mm × 52mm | 1 mm ~ 5 mm | |

| 0,065" | 60mm × 60mm | 1 mm ~ 5 mm | |

| 0.109" | 70mm × 70mm | 2 mm ~ 6 mm | |

| 0,120" | 75mm × 75mm | 2 mm ~ 6 mm | |

| 1 1/4" x 1 1/4" | 0,049" | 76mm × 76mm | 2 mm ~ 6 mm |

| 0,065" | 80mm × 80mm | 2 mm ~ 8 mm | |

| 0,072" | 85mm × 85mm | 2 mm ~ 8 mm | |

| 0,083" | 90mm × 90mm | 2 mm ~ 8 mm | |

| 0.109" | 95mm × 95mm | 2 mm ~ 8 mm | |

| 0,120" | 100mm × 100mm | 2 mm ~ 8 mm | |

| 0,135" | 120mm × 120mm | 4mm ~ 8mm | |

| 0,156" | 125mm × 125mm | 4mm ~ 8mm | |

| 0,188" | 130mm × 130mm | 4mm ~ 8mm | |

| 1 1/2" x 1 1/2" | 0,049" | 140mm × 140mm | 6mm ~ 10mm |

| 0,065" | 150mm × 150mm | 6mm ~ 10mm | |

| 0,072" | 160mm × 160mm | 6mm ~ 10mm | |

| 0,083" | 180mm × 180mm | 6mm ~ 12mm | |

| 0.109" | 200mm × 200mm | 6mm ~ 30mm | |

| 0,120" | 220mm × 220mm | 6mm ~ 30mm | |

| 0,140" | 250mm × 250mm | 6mm ~ 30mm | |

| 0,188" | 270mm × 270mm | 6mm ~ 30mm | |

| 0,250" | 280mm × 280mm | 6mm ~ 30mm | |

| 1 3/4" x 1 3/4" | 0,065" | 300mm × 300mm | 8mm ~ 30mm |

| 0,083" | 320mm × 320mm | 8mm ~ 30mm | |

| 0,095" | 350mm × 350mm | 8mm ~ 30mm | |

| 0.109" | 380mm × 380mm | 8mm ~ 30mm | |

| 0,120" | 400mm × 400mm | 8mm ~ 30mm | |

| 0,188" | 420mm × 420mm | 10mm ~ 30mm | |

| 2" x 2" | 0,049" | 450mm × 450mm | 10mm ~ 30mm |

| 0,065" | 480mm × 480mm | 10mm ~ 30mm | |

| 0,083" | 500mm × 500mm | 10mm ~ 30mm | |

| 0.109" | 550mm × 550mm | 10mm ~ 40mm | |

| 0,120" | 600mm × 600mm | 10mm ~ 40mm | |

| 0,145" | 700mm × 700mm | 10mm ~ 40mm | |

| 0,165" | 800mm × 800mm | 10mm ~ 50mm | |

| 0,188" | 900mm × 900mm | 10mm ~ 50mm | |

| 0,250" | 1000mm × 1000mm | 10mm ~ 50mm | |

| 0,312" | |||

| 2 1/4" x 2 1/4" | 0,188" | ||

| 0,250" | |||

| 2 1/2" x 2 1/2" | 0,083" | ||

| 0.109" | |||

| 0,120" | |||

| 0,188" | |||

| 0,250" | |||

| 0,312" |

| 3" x 3" | 0,083" |

| 0,120" | |

| 0,188" | |

| 0,250" | |

| 0,312" | |

| 0,375" | |

| 3 1/2" x 3 1/2" | 0,120" |

| 0,188" | |

| 0,250" | |

| 0,312" | |

| 0,375" | |

| 4" x 4" | 0,083" |

| 0,120" | |

| 0,156" | |

| 0,188" | |

| 0,250" | |

| 0,312" | |

| 0,375" | |

| 0.500" |

| 4 1/2" x 4 1/2" | 0,188" |

| 0,250" | |

| 0,312" | |

| 0,375" | |

| 5" x 5" | 0,188" |

| 0,250" | |

| 0,312" | |

| 0,375" | |

| 0.500" | |

| 6" x 6" | 0,188" |

| 0,250" | |

| 0,312" | |

| 0,375" | |

| 0.500" | |

| 0,625" | |

| 7 "x 7" | 0,188" |

| 0,250" | |

| 0,312" | |

| 0,375" | |

| 0.500" | |

| 0,625" |

| 8 "x 8" | 0,188" |

| 0,250" | |

| 0,312" | |

| 0,375" | |

| 0.500" | |

| 0,625" | |

| 9 "x 9" | 0,188" |

| 0,250" | |

| 0,312" | |

| 0,375" | |

| 0.500" | |

| 0,625" | |

| 10" x 10" | 0,188" |

| 0,250" | |

| 0,312" | |

| 0,375" | |

| 0.500" | |

| 0,625" | |

| 12" x 12" | 0,250" |

| 0,312" | |

| 0,375" | |

| 0.500" | |

| 0,625" | |

| 14" x 14" | 0,312" |

| 0,375" | |

| 0.500" | |

| 0,625" | |

| 16" x 16" | 0,312" |

| 0,375" | |

| 0.500" | |

| 0,625" |

Komposisi Kimia Bahan

| sasmita | unsur | C | Mn | P | S |

| ASTM A500 Gr.b | % | 0,05%-0,23% | 0,3%-0,6% | 0,04% | 0,04% |

| Acc.to EN10027/1 | Acc.to EN10027/2 | C% maks (WT Normal (mm) | Si% maks | Mn% maks | P% maks | S% maks | N% maks | |

| lan IC 10 | ≤ 40 | |||||||

| S235JRH | 1.0039 | 0.17 | 0.20 | - | 1.40 | 0.045 | 0.045 | 0.009 |

| S275JOH | 1.0149 | 0.20 | 0.22 | - | 1.50 | 0.040 | 0.040 | 0.009 |

| S275J2H | 1.0138 | 0.20 | 0.22 | - | 1.50 | 0.035 | 0.035 | - |

| S355JOH | 1.0547 | 0.22 | 0.22 | 0.55 | 1.60 | 0.040 | 0.040 | 0.009 |

| S355J2H | 1.0576 | 0.22 | 0.22 | 0.55 | 1.60 | 0.035 | 0.035 | - |

Sifat Mekanik Material

| sasmita | Kekuwatan Ngasilake | Kekuwatan Tensile | Elongation |

| A500.Gr.b | 46 ksi | 58 ksi | 23% |

| A513.GR.B | 72 ksi | 87 ksi | 10% |

| Unggah ungguh | Kekuwatan Ngasilake | Kekuwatan Tensile | Min.elogation | Min.persen properti | ||||||||

| Acc.to EN10027/1 lan IC 10 | Acc.to EN10027/2 | Normal WTmm | Normal WTmm | Longit. | nyabrang | Tes suhu°C | Rata-rata nilai impact min | |||||

| ≤16 | > 6 | > 40 | <3 | ≤3≤65 | Normal WTmm | |||||||

| ≤65 | ≤65 | ≤40 | > 40 | > 40 | ≤65 | |||||||

| ≤65 | ≤40 | |||||||||||

| S253JRH | 1.0039 | 235 | 225 | 215 | 360-510 | 340-470 | 26 | 25 | 24 | 23 | 20 | 27 |

| S275JOH | 1.0149 | 275 | 265 | 255 | 410-580 | 410-560 | 22 | 21 | 20 | 19 | 0 | 27 |

| S275J2H | 1.0138 | 275 | 265 | 255 | 430-560 | 410-560 | 22 | 21 | 20 | 19 | -20 | 27 |

| S355JOH | 1.0547 | 355 | 345 | 335 | 510-680 | 490-630 | 22 | 21 | 20 | 19 | 0 | 27 |

| S355J2H | 1.0576 | 355 | 345 | 335 | 510-680 | 490-630 | 22 | 21 | 20 | 19 | -20 | 27 |

Spesifikasi sing padha

| EN 10210-1 | NF A 49501 NF A 35501 | DIN 17100 DIN 17123/4/5 | BS 4360 | UNI 7806 |

| S235JRH | E 24-2 | St 37.2 | - | Fe 360 B |

| S275JOH | E 28-3 | St 44.3 U | 43 C | Fe 430 C |

| S275J2H | E 28-4 | St 44.3 N | 43 D | Fe 430 D |

| S355JOH | E 36-3 | St 52.3 U | 50 C | Fe 510 C |

| S355J2H | E 36-4 | St 52.3 N | 50 D | Fe 510 D |

| S275NH | - | Jalan E 285 N | - | - |

| S275NLH | - | TSt E 285 N | 43 EE | - |

| S355NH | E 355 R | Jalan E 355 N | - | - |

| S355NLH | - | TSt E 355 N | 50 EE | - |

| S460NH | E 460 R | Jalan E 460 N | - | - |

| S460NLH | - | TSt E 460 N | 55 EE | - |

- huruf blok "S" tegese "BAJA UNTUK APLIKASI STRUKTURAL"

- Figure sabanjuré tegese minimal.nilai ngasilaken dibutuhake kanggo kekandelan tembok ≤16 mm

- "J2" tegese nilai test impact -20 ° C min.27 jro

- huruf blok "H" tegese "BAGIAN KOWONG".

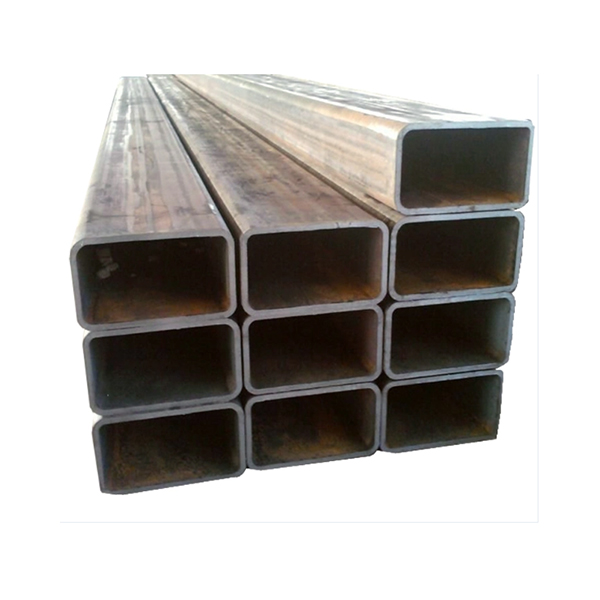

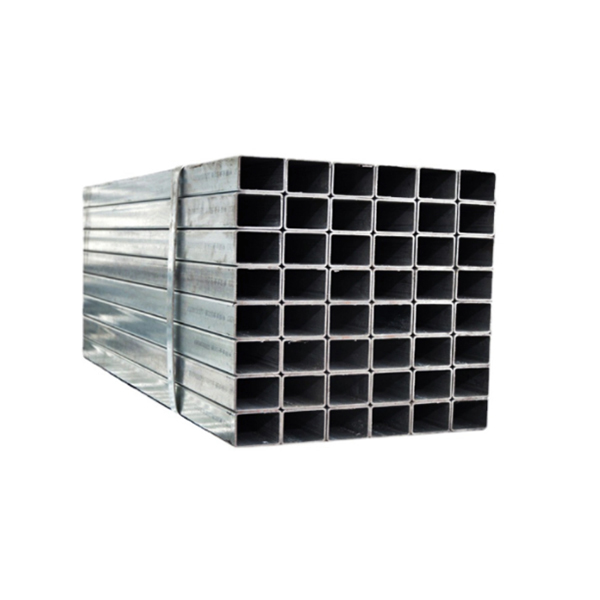

Tampilan produk